Our serives

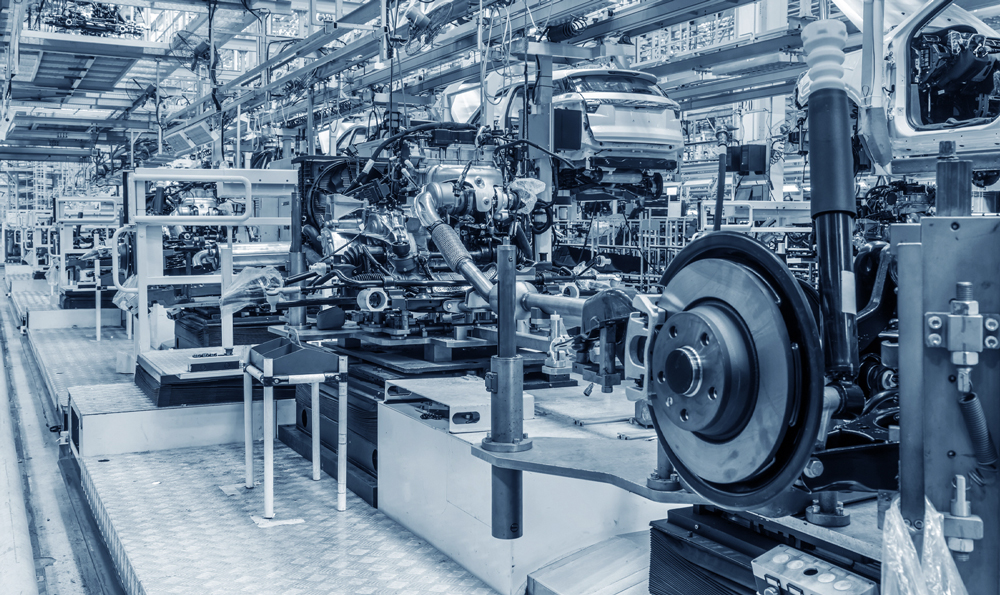

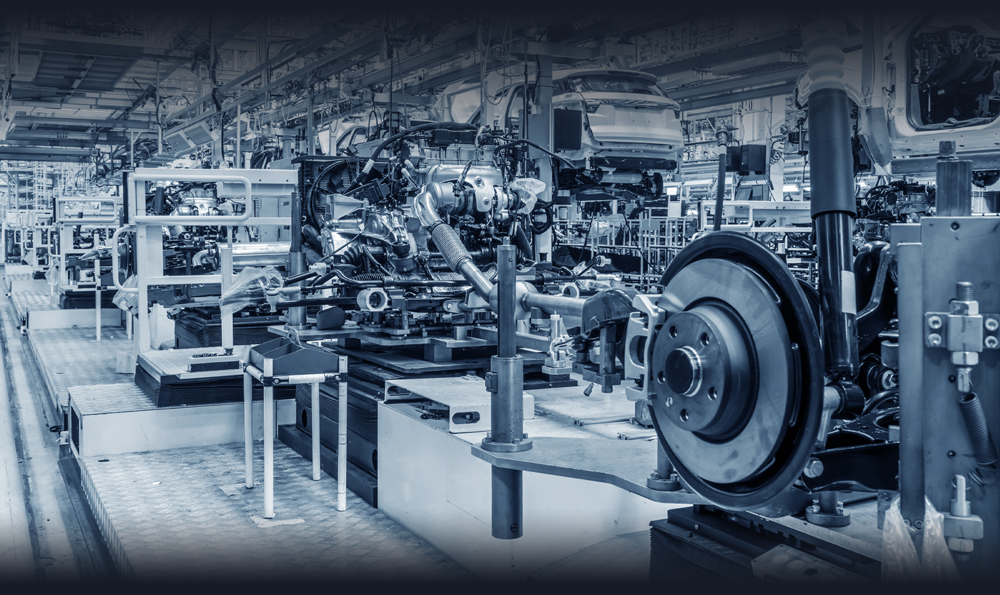

For more than 20 years, EPM (E stands for Engineering, P for Production and M for Management) cooperates with the automotive industry around the world to respond in an efficient and high-speed way.

Engineering - Production - Management -

Engineering - Production - Management -

Engineering - Production - Management -

Our services

We help Top Auto Manufacturers suppliers and OEMs Deliver on Launch, Operation and Lean Production. Optimization and competitiveness are part of our DNA that enables us to maintain the highest levels in all areas of the company and this industry. Our focus is to increase the efficiency, launch faster and reduce costs, which leads to an increase of profitability and continuous improvement systems.

01 Launch

- Process industrialization

- Plant transformation into AV & EV technology

- Launch coordination

- Process planning

- Plant transformation into AV & EV technology

- Launch coordination

- Process planning

02 Get back on track

03 Track & improve

04 Development

05 Incrase efficiency

What can we do for you

We support OEM automotive manufacturers, Tier1 system suppliers & Tier2 car manufacturing companies to deliver their commitments.

Services

01

Launch

- Process industrialization

- Plant transformation into AV & EV technology

- Launch coordination

- Process planning

02

Get back on track

- Improve your goals: Costs, Technical & quality, Time

- Don’t miss your milestone on plant/process delivery

03

Track & improve

- Cost reduction

- Performance optimization

- Industrialization 4.0

- Monitoring & analysis

04

Development

- Innovation

- Product concept development

- Industrialization concept development

05

Increase efficiency

- Increase throughput

- Reduce labor costs

- Increase OEE/uptime

- Reduce inventory

- Balance processes

- Balance processes

Monitoring & analysis

01. Monitoring & analysis

The definition, recording and presentation of the most important company key figures are essential for efficient company management and the identification of optimization potential. The KPI monitoring system developed by EPM makes it possible to adapt the key performance indicators to the specific company structure (are the KPIs adapted to the structure?) And to create the highest level of individual transparency.

The standardized IT tools in connection with a secured Cloud database, ensure a uniform, cross-plant and transnational working method. These analysis tools also enable the quick and efficient integration of ERP and production data. Semi-automated tools with a high degree of adaptation by EPM are used to monitor the project progress, the quality of the degree of fulfillment and the risk assessment.

The standardized IT tools in connection with a secured Cloud database, ensure a uniform, cross-plant and transnational working method. These analysis tools also enable the quick and efficient integration of ERP and production data. Semi-automated tools with a high degree of adaptation by EPM are used to monitor the project progress, the quality of the degree of fulfillment and the risk assessment.

01 Key figures

- Selection of most important Key Performance Indicators = KPIs.

- Clear definition of KPIs and determination of measurement criteria.

- Clear definition of KPIs and determination of measurement criteria.

02 Monitoring

03 Reporting

04 Task management

05 Launch performance

01. Monitoring & analysis

The definition, recording and presentation of the most important company key figures are essential for efficient company management and the identification of optimization potential. The KPI monitoring system developed by EPM makes it possible to adapt the key performance indicators to the specific company structure (are the KPIs adapted to the structure?) And to create the highest level of individual transparency.

The standardized IT tools in connection with a secured Cloud database, ensure a uniform, cross-plant and transnational working method. These analysis tools also enable the quick and efficient integration of ERP and production data. Semi-automated tools with a high degree of adaptation by EPM are used to monitor the project progress, the quality of the degree of fulfillment and the risk assessment.

01 Key figures

- Selection of most important Key Performance Indicators = KPIs.

- Clear definition of KPIs and determination of measurement criteria.

- Clear definition of KPIs and determination of measurement criteria.

02 Monitoring

03 Reporting

04 Task management

05 Launch performance

Process optimization

02. Process optimization

In order to maintain its competitiveness, a company must be prepared to continuously review and optimize all areas of the company. This applies even more so to acute problems in production or to short-term troubleshooting. EPM provides an experienced team to meet this challenge.

01 Performance monitoring

- Determining the most important key figures.

- Procedure for collecting and evaluating the defined key figures.

- Prepare meaningful reports and action logs.

- Procedure for collecting and evaluating the defined key figures.

- Prepare meaningful reports and action logs.

02 Production

03 Quality

04 Purchasing

05 Logistics

02. Process optimization

In order to maintain its competitiveness, a company must be prepared to continuously review and optimize all areas of the company. This applies even more so to acute problems in production or to short-term troubleshooting. EPM provides an experienced team to meet this challenge.

01 Performance monitoring

- Determining the most important key figures.

- Procedure for collecting and evaluating the defined key figures.

- Prepare meaningful reports and action logs.

- Procedure for collecting and evaluating the defined key figures.

- Prepare meaningful reports and action logs.

02 Production

03 Quality

04 Purchasing

05 Logistics

Cost reduction

03. Cost reduction

When it comes to reducing costs, the interdisciplinary team at EPM not only focuses on directly visible waste (Japanese: muda), but also attacks the causes of this waste, which are identified as being caused by irregularities (Japanese: mura) and overloading (Japanese: muri) of systems, resources and employees.

The EPM team integrates the identified potentials together with the on-site processes of the customer. Parallel to this, the shop floor management is set up, with which the improvements are furthered through Kaizen activities. EPM sees the goal of a cost reduction project achieved when the improvements have been incorporated into the customer’s processes in a sustainable and automated manner. The big advantage of the EPM approach is thus the speed at which this can be done.

The EPM team integrates the identified potentials together with the on-site processes of the customer. Parallel to this, the shop floor management is set up, with which the improvements are furthered through Kaizen activities. EPM sees the goal of a cost reduction project achieved when the improvements have been incorporated into the customer’s processes in a sustainable and automated manner. The big advantage of the EPM approach is thus the speed at which this can be done.

01 Muda = Waste

Muda is often translated as “waste”, but it means much more than that. Muda is any activity that does not directly add value and is the basic concept of the Monozukuri principle (Monozukuri is Japanese for “making things”). In this sense, necessary processes, such as the shipment of products, are constantly under critical scrutiny. Seven types of waste are used to identify Muda

02 Mura = Irregularity

03 Muri = Overload

03. Cost reduction

When it comes to reducing costs, the interdisciplinary team at EPM not only focuses on directly visible waste (Japanese: muda), but also attacks the causes of this waste, which are identified as being caused by irregularities (Japanese: mura) and overloading (Japanese: muri) of systems, resources and employees.

The EPM team integrates the identified potentials together with the on-site processes of the customer. Parallel to this, the shop floor management is set up, with which the improvements are furthered through Kaizen activities. EPM sees the goal of a cost reduction project achieved when the improvements have been incorporated into the customer’s processes in a sustainable and automated manner. The big advantage of the EPM approach is thus the speed at which this can be done.

01 Muda = Waste

Muda is often translated as “waste”, but it means much more than that. Muda is any activity that does not directly add value and is the basic concept of the Monozukuri principle (Monozukuri is Japanese for “making things”). In this sense, necessary processes, such as the shipment of products, are constantly under critical scrutiny. Seven types of waste are used to identify Muda

02 Mura = Irregularity

03 Muri = Overload

Project planning

04. Project planning & launch coordination

Efficiency and experience in detailed and comprehensive planning are key elements of a successful SOP. Sustainable technical expertise and practical experience are a must. A launch team from EPM provides the interdisciplinarity for the challenges from the start of development to successful series production. This is a service that EPM has provided for a wide variety of possibilities with high technical and geographical complexity for years.

Project planning / detailed services:

- Product responsibility for the entire development process.

- Start: surface analysis of Class A surfacing/basic engineering concept.

- Completion: PPAP Green, series production (SOP + 3 months).

- OEM/customer management throughout the entire project period.

- Moderation of FMEA (design/process/product).

- Tool concept planning.

- Industrialization planning of mechanical concepts/forms/machines.

- Tolerance analyses: calculation/negotiation/fulfilment of capabilities.

- Function test: planning and conducting.

- Operating equipment: tracking, sampling, testing, relocating.

- Project management (commercial and scheduling responsibility).

- Planning and evaluation of processes, process capability analyses, measurement system analyses.

- Interactive, daily-based project management.

- Project handover to local production and assembly plant as per OEM/Tier 1 standards.

- Project conclusion with PPAP Green.

- Product responsibility for the entire development process.

- Start: surface analysis of Class A surfacing/basic engineering concept.

- Completion: PPAP Green, series production (SOP + 3 months).

- OEM/customer management throughout the entire project period.

- Moderation of FMEA (design/process/product).

- Tool concept planning.

- Industrialization planning of mechanical concepts/forms/machines.

- Tolerance analyses: calculation/negotiation/fulfilment of capabilities.

- Function test: planning and conducting.

- Operating equipment: tracking, sampling, testing, relocating.

- Project management (commercial and scheduling responsibility).

- Planning and evaluation of processes, process capability analyses, measurement system analyses.

- Interactive, daily-based project management.

- Project handover to local production and assembly plant as per OEM/Tier 1 standards.

- Project conclusion with PPAP Green.

04. Project planning & launch coordination

Efficiency and experience in detailed and comprehensive planning are key elements of a successful SOP. Sustainable technical expertise and practical experience are a must. A launch team from EPM provides the interdisciplinarity for the challenges from the start of development to successful series production. This is a service that EPM has provided for a wide variety of possibilities with high technical and geographical complexity for years.

Project planning / detailed services:

- Product responsibility for the entire development process.

- Start: surface analysis of Class A surfacing/basic engineering concept.

- Completion: PPAP Green, series production (SOP + 3 months).

- OEM/customer management throughout the entire project period.

- Moderation of FMEA (design/process/product).

- Tool concept planning.

- Industrialization planning of mechanical concepts/forms/machines.

- Tolerance analyses: calculation/negotiation/fulfilment of capabilities.

- Function test: planning and conducting.

- Operating equipment: tracking, sampling, testing, relocating.

- Project management (commercial and scheduling responsibility).

- Planning and evaluation of processes, process capability analyses, measurement system analyses.

- Interactive, daily-based project management.

- Project handover to local production and assembly plant as per OEM/Tier 1 standards.

- Project conclusion with PPAP Green.

Got a project?

Let's talk!

USA

1500 Broadway, Suite 1902, New York, New York 10036

+1 646 464 0788

info@ep-m.com

+1 646 464 0788

info@ep-m.com

Germany

Ridlerstr. 57, 80339

München

+49 089 2354 8223

info@ep-m.de

München

+49 089 2354 8223

info@ep-m.de

Got a project?

Let's talk!

USA

1500 Broadway, Suite 1902, New York 10036

+1 646 464 0788

info@ep-m.com

+1 646 464 0788

info@ep-m.com

Germany

Ridlerstr. 57, 80339, München

+49 089 2354 8223

info@ep-m.com

+49 089 2354 8223

info@ep-m.com